Solutions For Food Applications

Safe Quality Food (SQF Institute) Certification

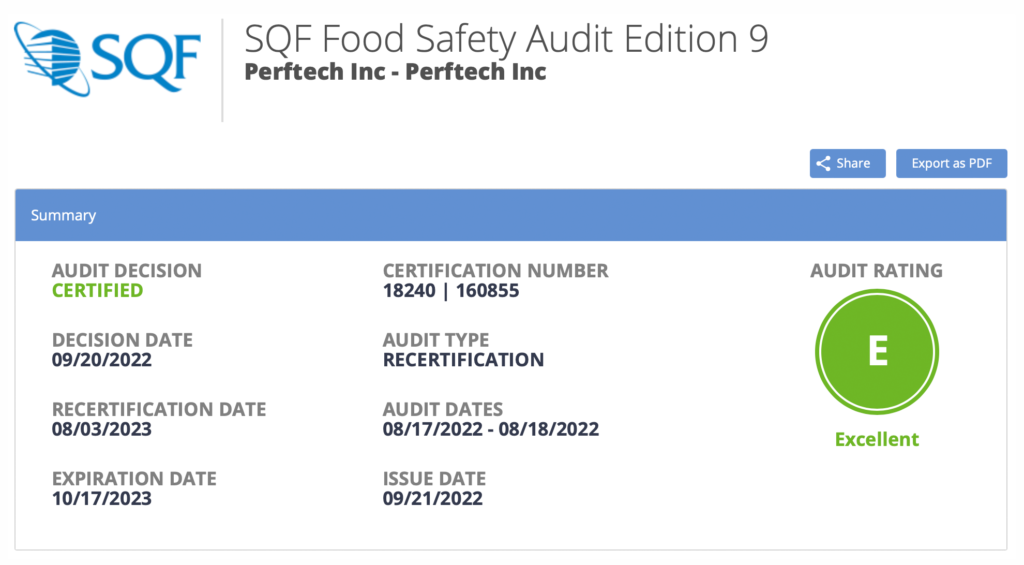

Perftech has been granted Safe Quality Food Certification (SQF Code Edition 9: Manufacture of Food Packaging). SQF is a comprehensive HACCP-based food safety and quality management certification system recognized by the Global Food Safety Initiative. It communicates that producers, suppliers, retailers and consumers are assured of safe, quality food products. SQF certification likewise guarantees greater trust and acceptance among each supplier in the “farm to fork” chain. Perftech has received an Excellent Rating from SQF each year since 2018. We maintain a total commitment to the highest standards for facility hygiene and cleanliness. Our new facility was specially designed for optimal efficiency and hygiene. From our high-gloss painted floor to shatter-proof ceiling fixtures, Perftech has taken great care to ensure our facility meets the most demanding requirements for food packaging material supplied to the industry. Our HAACP-based program ensures that our customers can count on us to safeguard both their material and their reputation.

Here are just a few examples of where our perforation adds value to common substrates:

Fresh-cut produce

Each variety of fresh-cut produce requires a specific headspace inside the package for optimal shelf-life extension. In many cases, commonly used lidding and bag films cannot provide or maintain that headspace because of the film’s inherent barrier qualities.

Microperforation by Perftech’s high-tech laser systems permits the film to “breathe” at appropriate rates for the produce within. Perftech was a pioneer in the adoption of laser perforation for tailoring Oxygen Transmission Rate (OTR), Moisture Vapor Transmission Rate (MVTR) and CO2 transmission rates for these applications. Our experience and extensive database of solutions allow us to quickly design the perforation pattern to meet your exact requirements.

Microwaveable frozen vegetables and ready-to-eat meals

Frozen-food packaging requires a robust but cost-effective flexible film to withstand freezing and distribution. Customers frequently demand steam-cooking convenience. How do you vent steam from these tough, sealed packages? The simplest and most efficient solution is laser perforation. Our powerful, state-of-the-art lasers provide custom patterns optimized for your specific food packaging application.

Meat pads

Foam trays for Chicken, Beef, Pork and other proteins often use super-absorbent tray-liner pads to absorb fluids and keep the product fresh and appealing. Our hot-needle perforation provides just the right amount of porosity to the film enveloping the absorbent core. Careful attention to hole size and formation creates a simple and inexpensive one-way valve that helps ensure the fluid stays absorbed.

Cereal tray lidding

Rigid trays packed with moisture-sensitive cereals and sealed with barrier lidding can be challenging to distribute over mountains or at altitude. Pressure builds up inside the container, potentially bursting seals. Laser microperforation of the lidding lets the headspace adjust to outside pressure, eliminating burst seals while reinforcing quality and maintaining shelf-life.

Get started on your application solution

Contact us at (630) 554-0010 today to explore how perforation may be used to enhance your food packaging material.

*Modified Atmosphere Packaging (MAP) is the enclosure of food in a package where the atmosphere inside the package is modified to provide an optimum atmosphere for increased shelf life and food quality. MAP is applied in the food industry to extend shelf life and preserve freshness, flavor and safety of fresh and fresh-cut perishable foods. It also prevents discoloring, ensuring an aesthetically pleasing shelf appeal.

Learn more about SQF Institute, Global Food Safety Initiative, HAACP